Product Categories

- Arduino Shields

- Breakout Boards

- CAN (Controller Area Network)

- Connectors and Interconnect

- Drivers, DACs & Outputs

- FIRST Robotics Competition

- Formula SAE

- Hardware

- Interface and Logging

- Power Supplies and Distribution

- Qwiic Connect System

- R3aktor Data Acquisition

- Sensors

- Software

- Switches, Encoders, & Buttons

- Temperature Measurement

- Wire

- Discontinued

Tech Article Categories

Table of Contents

Posted: April 20, 2014

Modified: April 29, 2014

Home > Tech Article Categories > Temperature Measurement > Wiring for RTD Configurations

Wiring for RTD Configurations

Introduction

There are three different RTD configurations supported by the SEN-30201/2 breakout boards, as well as two different type options available. The board is ‘hard-coded’ for RTD type (PT100 vs PT1000 or custom), but jumper wires may be used on the input screw terminal block to readily switch between 2-, 3- and 4-wire RTDs for your application. Put another way, if you buy a PT100 board, you can use it to read 2-, 3- or 4-wire RTDs by simply adding or subtracting jumper wires between input terminals on the board. Read the next few paragraphs for RTD type/configuration selection for your application or skip to the bottom for wiring diagrams.

Prior to selecting an RTD configuration, it is important to know just how RTDs are ‘read’. As the name implies (Resistance Temperature Device), the resistance of an RTD element changes with respect to the temperature of the element. By passing a small, known current through the device, the resistance can be measured. The most precise way is to use a ‘Kelvin’ connection at the device, which uses 4 wires to accomplish the measurement task. Two leads, the Force+ and Force- connections on a 4-wire RTD, pass the current to the RTD. Two additional leads, RTD+ and RTD-, connect to Force+ and Force-, respectively, at the RTD element. A high-impedance sink (ADC or multimeter) reads the voltage differential across the RTD+ and RTD- leads and multiplies by the known current flowing to get resistance. Simple, right? The Force+ and Force- leads are not even required to have the same length or resistance to get an accurate measurement on a 4-wire device, which makes it good for virtually any lead length (assuming cost and wiring challenges are not big factors). Which takes us to the other options.

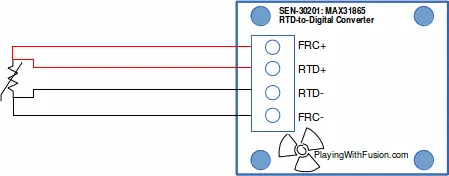

4-Wire Connection

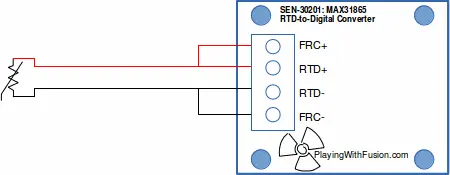

As mentioned, 4-wire RTDs have a number of benefits, largely surrounding the precision domain. However, 2-wire RTDs have fewer wires to run and connect than 3- or 4-wire RTDs (stating the obvious), which makes running wires cheaper and simpler in applications where precision can be sacrificed to varying degrees. Some applications see minimal degradation in measurement. For instance, in applications where the RTD probe is within inches or a few feet of the sensor board. In this case, wire resistance is not high enough to interfere with (offset) the reading of the RTD element. In other cases, precision requirements are low enough that using even long wires is not an issue. In these cases, 2- RTDs may be sufficient.

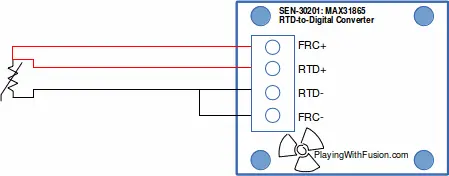

3-Wire Connection

3-wire RTDs exist, too. True to their name, they have three wires that are to be used. The idea here is that the Force+ wire is identical in spec (resistance) to the RTD- wire. The voltage differential between Force+ and RTD+ is subtracted from the measurement between RTD+ and RTD- to get an accurate reading. The 3-wire RTD has the precision benefits of the 4-wire device (though requires an assumption about identical lead resistances) with the benefit of one fewer wire to connect.

2-Wire Connection

Conclusion

So now that connection options have been covered, the question becomes, “how do I use any of these things with the Playing With Fusion SEN-30201/2 RTD-to-Digital Converter breakout boards?” Well, first you must select the RTD type that you want to use. The board you receive will only be capable of reading either a PT100 or PT1000 type RTD (or custom resistance if you contact us), so make sure you order the one you need. Next, pick your connection style. As discussed above, there are 2-, 3- and 4-wire RTDs available. Start by connecting the wires as they are labeled to the screw terminals. If not labeled, connect the red wires to the + side of the screw terminal block, starting with RTD+ terminal, and working your way out. Connect the black wires to the – side of the screw terminal block, starting with the RTD- terminal, and working your way out. If the colors are different than mentioned here, send us an email and we will do what we can to help out! Next, jumper (I use breadboard jumpers) any unfilled screw terminals to the terminal adjacent to it (next to it).

Now configure your software for connection type and run it! Check out the Playing With Fusion Arduino library for coding details.

External Links

| RTD Sensor Overview | Industrial Quick Search article describing RTD sensor types and measurement methods |

PT100 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

PT100 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

PT1000 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

PT1000 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

Dual PT100 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

Dual PT100 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

Dual PT1000 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

Dual PT1000 RTD Temperature Sensor SPI Digital Interface MAX3186 Breakout

Quad PT100 RTD Temperature Sensor Shield

Quad PT100 RTD Temperature Sensor Shield

Quad PT1000 RTD Temperature Sensor Shield

Quad PT1000 RTD Temperature Sensor Shield